British double-glass module processing plant

Welcome to our dedicated page for British double-glass module processing plant! Here, we have carefully selected a range of videos and relevant information about British double-glass module processing plant, tailored to meet your interests and needs. Our services include high-quality British double-glass module processing plant-related products and solutions, designed to serve a global audience across diverse regions.

We proudly serve a global community of customers, with a strong presence in over 20 countries worldwide—including but not limited to the United States, Canada, Mexico, Brazil, the United Kingdom, France, Germany, Italy, Spain, the Netherlands, Australia, India, Japan, South Korea, China, Russia, South Africa, Egypt, Turkey, and Saudi Arabia.

Wherever you are, we're here to provide you with reliable content and services related to British double-glass module processing plant, including cutting-edge solar energy storage systems, advanced lithium-ion batteries, and tailored solar-plus-storage solutions for a variety of industries. Whether you're looking for large-scale industrial solar storage or residential energy solutions, we have a solution for every need. Explore and discover what we have to offer!

Canadian Solar TOPCon Module Technical White Paper

Since 2019, CSI Solar has been developing N-type TOPCon (Tunnel Oxide Passivated Contacts) technologies, and now launches a diversified TOPCon module portfolio covering both 182mm

Read more

Glass-Glass PV Modules

Double-glass modules boast increased reliability, especially for utility scale PV projects. These include better resistance to higher temperatures, humidity and UV conditions and have better

Read more

Steps and layout of solar module manufacturing

The solar module manifacturing process is performed at an industrial level by special machines which assemble the various parts semi

Read more

Second Wave Of Innovation For Double Glass Modules

There may be an easy-to-see increase in the second half of 2019," says Gessey PV Consulting in China. In March this year, Trina Solar released

Read more

SOLAR/PV EQUIPMENT – Semiphoton

Our automated Solar/PV modules production line includes a complete set of equipment, such as solar cells laser cutting, string soldering, welding, glass loading, layup,

Read more

Glass-Glass PV Modules

Double-glass modules boast increased reliability, especially for utility scale PV projects. These include better resistance to higher temperatures, humidity and

Read more

China 166 Double Glass Module Series manufacturers, 166 Double Glass

The 166 Double Glass Module Series is a new design, through excellent processing technology and high-quality raw materials, the performance of 166 Double Glass Module Series up to a

Read more

Towards 50 Year Lifetime PV Modules: Double Glass vs. Glass

The choice of a double glass (DG) or glass/backsheet (GB) module leads to two very different chemical (e.g., O2, H2O) and mechanical environments (e.g., mechanical stress

Read more

What are Double Glass Solar Panels?

If you find your home unsuitable for glass-glass modules, the Anker SOLIX balcony power plant is a great alternative. It features monocrystalline panels

Read more

The weekend read: Double glass can spell double

Highly transparent allowing power generation on both sides of the module, robust in some of the toughest elements, and able to remain in the

Read more

Towards 50 Year Lifetime PV Modules: Double Glass vs.

The choice of a double glass (DG) or glass/backsheet (GB) module leads to two very different chemical (e.g., O2, H2O) and mechanical environments (e.g., mechanical stress

Read more

Dow Corning and BYD developed Si-encapsulation double-glass module

The DuPont Oval Logo, DuPont™, and all products denoted with ® or ™ are trademarks or registered trademarks of E. I. du Pont de Nemours and Company or its affiliates.

Read more

The weekend read: Double glass can spell double trouble

Highly transparent allowing power generation on both sides of the module, robust in some of the toughest elements, and able to remain in the field or on the roof for 30, 40, or

Read more

Single-glass versus double-glass: a deep dive into module

Double-glass modules, with their performance in the face of salt mist, high temperatures and high humidity, have won the market''s favour. However, this trend is not

Read more

Everything You Need to Know About Glass Glass Solar Modules

If you find your home unsuitable for glass-glass modules, the Anker SOLIX balcony power plant is a great alternative. It features monocrystalline panels with up to 25% efficiency, surpassing

Read more

Double the strengths, double the benefits

In contrast, double glass modules replace the polymer layer with another glass sheet, creating a robust sandwich structure. At IBC SOLAR, we

Read more

Double the strengths, double the benefits

In contrast, double glass modules replace the polymer layer with another glass sheet, creating a robust sandwich structure. At IBC SOLAR, we use 2,0 mm x 2,0 mm glass

Read more

Double the strengths, double the benefits

In the ever-evolving world of photovoltaic technology, double glass solar modules are emerging as a game-changer. By encapsulating solar cells

Read more

Dow Corning and BYD developed Si-encapsulation

The DuPont Oval Logo, DuPont™, and all products denoted with ® or ™ are trademarks or registered trademarks of E. I. du Pont de Nemours and

Read more

Consider Modular Plant Design

In a modular plant, the process equipment, instrumentation, valves, piping components, and electrical wiring are mounted within a structural steel framework (i.e ., skid or module). Heat

Read more

SOLAR/PV EQUIPMENT – Semiphoton

Our automated Solar/PV modules production line includes a complete set of equipment, such as solar cells laser cutting, string soldering, welding, glass loading, layup, laminating, framing, J

Read more

New Glass Processing Plant For Qatar | British Glass

A newly formed joint venture is investing US$40M to set up one of the largest glass processing facilities in the UAE region. Nasser Bin Khalid and Sons Holding Company, Al Seal

Read more

Monocrystalline Half-Cell Bifacial Double Glass Module: Growth

The monocrystalline half-cell bifacial double-glass module market is experiencing robust growth, driven by increasing demand for high-efficiency solar energy solutions. This segment benefits

Read more

What are Double Glass Solar Panels?

The double glass module, as the name implies, is a construction in which the typical aluminum frames and back sheet substrate are replaced by another glass panel.

Read moreFAQs 6

Why do bifacial modules need 2 mm glass?

As a result of the additional cost of very thin glass, most mass production bifacial modules being produced today are described as using 2 × 2.5 mm glass. More often, this means 3.2 mm on the front and 2 mm backsheet glass, states Weilharter – which brings down costs but in turn introduces its own issues.

What is a glass-glass module?

Glass-Glass module designs are an old technology that utilises a glass layer on the back of modules in place of traditional polymer backsheets. They were heavy and expensive allowing for the lighter polymer backsheets to gain the majority of the market share at the time.

What is the difference between tempered glass and glass-foil modules?

Compared to traditional glass-foil modules, which are about 18 kg, this is a 20% increase in weight. Although there is no standard on glass thickness, in general it is a more complex and expensive process to produce very thin, tempered glass. However, 2.5 mm glass thickness does allow for frameless designs, which can reduce costs dramatically.

What changes are incorporated in glass-glass modules?

Another major change that is also incorporated for glass-glass modules is swapping EVA for polyolefins as an encapsulant. This is due to the free radicals produced during the cross-linking lamination process of EVA. While traditional backsheets are somewhat permeable to the free radicals, the double-glass module is not.

Are bifacial double-glass modules a good choice?

There has been a noteable shift from the initial single-facial single-glass modules to bifacial double-glass modules. Double-glass modules, with their performance in the face of salt mist, high temperatures and high humidity, have won the market’s favour. However, this trend is not without its risks.

What are the benefits of double-glass solar panels?

Source : ITRPV Fig 16b Double-glass modules boast increased reliability, especially for utility scale PV projects. These include better resistance to higher temperatures, humidity and UV conditions and have better mechanical stability, reducing the risk of microcracks during installation and operation.

Related Contents

- Inverter 12v maximum output

- US version energy storage inverter

- Photovoltaic energy storage industry production

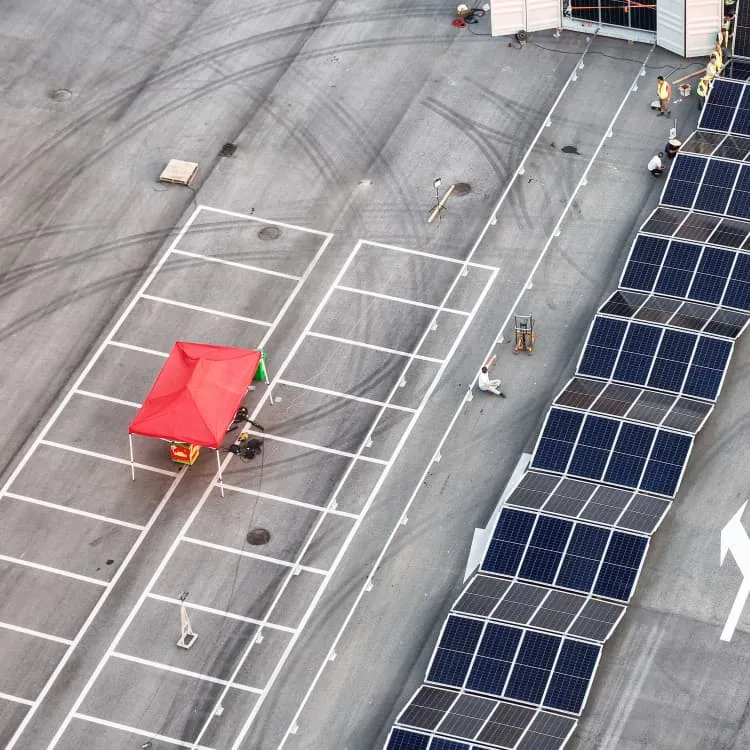

- Malaysia Solar Photovoltaic Panel Project

- North Macedonia Solar Base Station Company China

- Energy storage fire protection product research and development

- Can a sine wave inverter be made into a single stage

- Czech Energy Storage Power Station New Energy Engineering Design

- Spanish independent energy storage project

- Technology for making lithium battery station cabinets

- Marshall Islands Containerized Lithium Battery System

- 3360w solar system

- 200V sine wave inverter

- Is 400 watts of solar panels enough