Pack battery factory advantages

Welcome to our dedicated page for Pack battery factory advantages! Here, we have carefully selected a range of videos and relevant information about Pack battery factory advantages, tailored to meet your interests and needs. Our services include high-quality Pack battery factory advantages-related products and solutions, designed to serve a global audience across diverse regions.

We proudly serve a global community of customers, with a strong presence in over 20 countries worldwide—including but not limited to the United States, Canada, Mexico, Brazil, the United Kingdom, France, Germany, Italy, Spain, the Netherlands, Australia, India, Japan, South Korea, China, Russia, South Africa, Egypt, Turkey, and Saudi Arabia.

Wherever you are, we're here to provide you with reliable content and services related to Pack battery factory advantages, including cutting-edge solar energy storage systems, advanced lithium-ion batteries, and tailored solar-plus-storage solutions for a variety of industries. Whether you're looking for large-scale industrial solar storage or residential energy solutions, we have a solution for every need. Explore and discover what we have to offer!

Battery Technology & Manufacturing Insights

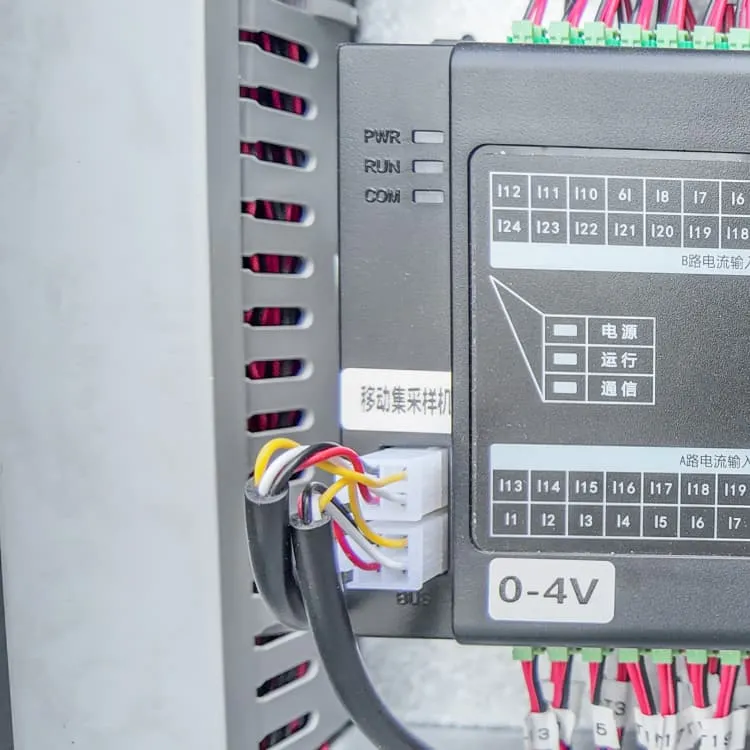

Notably, manufacturers will require support on the optimization of battery production and facility construction, as well as battery management

Read more

The advantages of more elegant circuit design in battery packs

Modern battery packs are often designed with two competing needs in mind. On the one hand, the primary purpose of batteries is to localize power needs. By definition, battery

Read more

Introduce battery lithium pack factory Advantages

Control the quality of battery lithium pack from the source of battery cells. Meet customers'' diverse, one-stop service needs. Two automated PACK production lines. More than 160

Read more

Advantages of lithium battery PACK factory automation

With state-of-the-art automation, the production line at MK Lithium Battery pack factory not only accelerates the pace of manufacturing but also

Read more

Advantages of lithium battery PACK factory automation

With state-of-the-art automation, the production line at MK Lithium Battery pack factory not only accelerates the pace of manufacturing but also elevates the standards of

Read more

Custom Lithium Battery Pack Manufacturing

Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering requirements, selecting cells, concurrent

Read more

U.S. Battery Gigafactories [2025 List] | EV Supply Chain

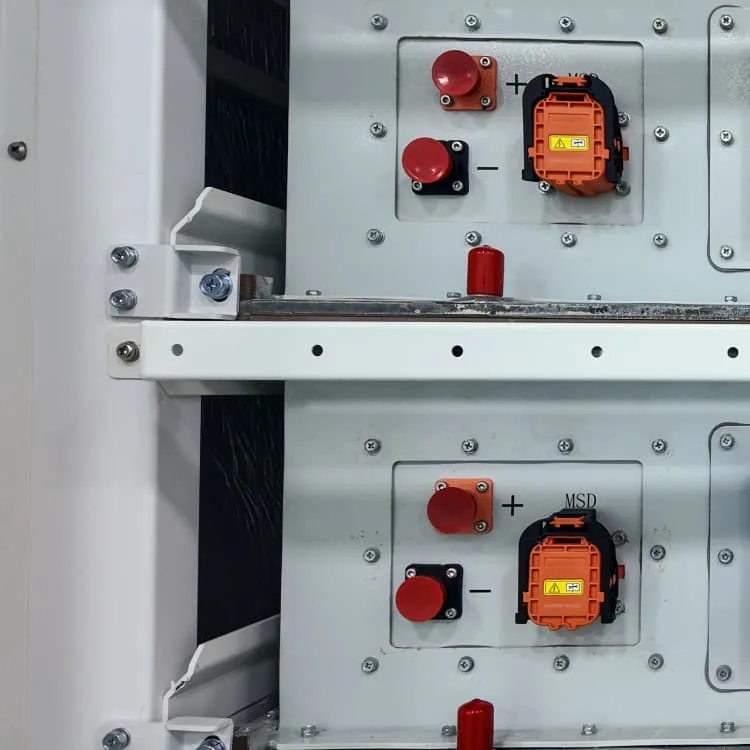

Battery packs combine electrochemical cells with mechanical, electrical, and thermal subsystems to ensure reliable operation across vehicle lifetimes. Pack assembly is increasingly integrated

Read more

How Do Lithium-Ion Battery Packs Work and What Are Their

Lithium-ion battery packs feature high energy density, lightweight design, and long cycle life. They include multiple cells combined for desired voltage and capacity, a Battery Management

Read more

advantages and disadvantages of the lithium-ion battery from

Ion batteries from a custom lithium ion battery pack supplier or factory. The lithium- Ion batteries are one of the most popular options for consumer and portable electronics. High performance

Read more

Battery Packs Explained: How They Work, Usage, and a

What Are Battery Packs and How Do They Work? Battery packs are portable power sources that store electrical energy for later use. They typically consist of multiple

Read more

Advantages And Disadvantages Of The Lithium-Ion Battery From

67 Huizhou JB Battery Technology Limited is one of the leading custom lithium ion battery pack manufacturers from China, which is capable of designing and supplying portable

Read more

Exploring Battery Packs: Manufacturing, Advantages, and

As with any electrical device, battery packs have their advantages and disadvantages. Whether considering their chemical composition, power capacity, or storage capabilities, several factors

Read more

BESS Acceptance Testing (FAT / SAT)

Utilize BESSential, our comprehensive quality control service for battery energy storage systems (BESS) and benefit from our partnership with Sinovoltaics.

Read more

24V Plastic Shell Lifepo4 Battery Pack

As one of the most professional plastic shell 24v lifepo4 battery pack manufacturers and suppliers in China, we''re featured by quality products and competitive price. Please rest assured to buy

Read more

Battery Pack Manufacturing Process

The battery pack manufacturing process involves cell selection, module assembly, wiring, thermal management, and safety integration. Each step ensures efficiency, reliability,

Read more

Reliance building largest battery plant in India

Reliance Industries has committed INR 75,000 crore (almost 9 billion USD) to establish an integrated manufacturing ecosystem for solar value chain, battery energy storage

Read more

How Do Lithium-Ion Battery Packs Work and What Are Their Advantages?

Lithium-ion battery packs feature high energy density, lightweight design, and long cycle life. They include multiple cells combined for desired voltage and capacity, a Battery Management

Read more

U.S. Battery Gigafactories [2025 List] | EV Supply

Battery packs combine electrochemical cells with mechanical, electrical, and thermal subsystems to ensure reliable operation across vehicle lifetimes. Pack

Read more

Everything You Need To Know About Tesla''s Lithium

Lithium-ion batteries are what make battery-electric vehicles (BEVs) possible and Tesla builds the epitome of such long-range EVs. What''s there to know?

Read more

China Metal Shell Lifepo4 Battery Pack Manufacturers Suppliers Factory

As one of the most professional metal shell lifepo4 battery pack manufacturers and suppliers in China, we''re featured by quality products and competitive price. Please rest assured to buy

Read more

Lithium-ion Battery Pack Manufacturing Process & Design

By complying with strict quality control standards and advances in lithium battery technology, battery pack manufacturers can produce high-quality, safe, and reliable battery

Read more

Key Benefits of Fully Automatic Battery Pack Assembly

One of the most significant advancements in this field is the shift towards fully automatic battery pack assembly. This article explores several key benefits associated with this cutting-edge

Read more

Custom Battery Pack Charge Discharge Machine,Battery Pack

Find and request a quote for Battery Pack Charge Discharge Machine from ACEY. We are offering our customers a wide range of lithium-ion batteries and supercapacitor.

Read more

Cylindrical Battery Pack Production Line: Advantages Driving the

Discover the advantages of cylindrical battery pack production lines, including high automation, boosted efficiency, cost reduction, consistent quality, and enhanced safety. Learn

Read more

Battery Enclosures | Kautex

Pentatonic™ Battery Enclosures _ Our fully composite, lightweight Pentatonic cell to pack and cell to module battery enclosures can be manufactured to fit any

Read more

Custom Lithium Battery Pack Manufacturing

Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering

Read more

Welding Technologies for Battery Packs: an Overview

The battery pack/battery module manufacturing process is extremely labour-intensive. Automating the battery tab welding process is

Read moreFAQs 6

What makes a successful battery pack manufacturing process?

Effective cell selection and procurement lay the groundwork for successful battery pack manufacturing, directly impacting the quality and performance of the final product. The battery cell manufacturing process is a complex, multi-step procedure that ensures the efficiency, safety, and longevity of battery packs.

What is battery pack production?

In conclusion, Battery pack production is a complex and multifaceted process that requires meticulous attention to detail, strict quality control, and a commitment to safety.

Why do you need a custom battery pack?

Customization ensures optimal performance, safety, and efficiency for various applications, including electric vehicles (EVs), consumer electronics, and energy storage systems. 1. Customizing Battery Packs for Specific Requirements

What makes a good battery pack?

The foundation of any high-performance battery pack begins with selecting the right battery cells. This critical decision influences the overall performance, lifespan, safety, and cost of the final battery pack. Different applications require specific types of battery cells based on their unique characteristics:

What makes a custom lithium-ion battery pack unique?

The foundation of any custom lithium-ion battery pack lies in the selection of the integrated cells. Our cell selection for custom packs involves: Lithium-ion cell advancements continue expanding performance boundaries yearly. Leveraging state-of-the-art cell technology is crucial for maximizing custom pack capabilities.

How do you make custom lithium-ion battery packs?

Key Takeaway: Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering requirements, selecting cells, concurrent engineering, prototyping, certification, production planning, and lifecycle support.

Related Contents

- Solar Water Pump Inverter Battery Module

- Are flow batteries widely used

- Namibia lithium energy storage power

- 620W Micro PV Inverter

- Algeria inverter power generation home solar power generation home

- Côte d Ivoire communications industry base station

- India Energy Storage Battery Project

- Yemen Heavy Industry Energy Storage Cabinet Model

- Flywheel energy storage related companies

- South Ossetia Energy Storage Battery Use

- Morocco Casablanca Peak Valley Energy Storage Project

- Inverter can change the output power

- What does perc high-efficiency component mean

- Energy storage mobile power supply voltage is low